AUDI JETTA PASSAT 09G 09M – ATSG

27-03-2025, 03:07. Posted by: carsoftos777

This manual contains the procedures necessary to diagnose, rebuild and/or repair the 09G/09M transaxle and is intended for automotive technicians that are familiar with the operation of automatic transmissions.

Transaxle, which is a 6 speed, fully automatic and electronic controlled transaxle. Volkswagen engineers were also involved, in conjunction with Aisin, in the development process for their vehicles and they gave it the 09G/09M designation. BMW gave it the designation 6F21WA for their Mini-Cooper.

The 09G/09M transaxle is used in a wide variety of applications and engine sizes. As a result, the number of friction plates, planetary ratios, intermediate ratios and final drive ratios will vary depending on torque load requirements of the specific vehicle. The TF60SN transaxle uses a gear ratio sensitive system, requiring the correct transaxle interchange. The TF60-SN is used in the BMW Mini Cooper, Volkswagen and Audi vehicles.

The 09G/09M transaxle uses a Lepelletier arrangement, using a simple planetary coupled with a Ravigneaux planetary. This arrangement makes six forward speeds and reverse possible, with only five clutch packs and one freewheel.

Volkswagen Transporter T5

2007 Volkswagen Jetta, US market

2009 Volkswagen Tiguan, US market

various Seat, Skoda, Audi models

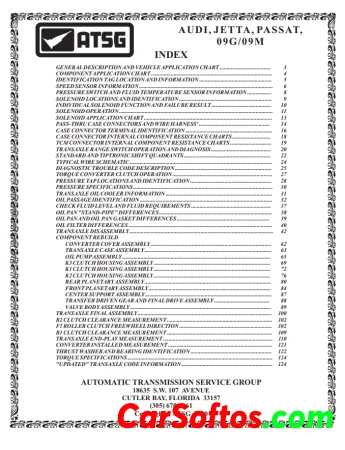

CONTENTS

GENERAL DESCRIPTION AND VEHICLE APPLICATION CHART

COMPONENT APPLICATION CHART

IDENTIFICATION TAG LOCATION AND INFORMATION

SPEED SENSOR INFORMATION

PRESSURE SWITCH AND FLUID TEMPERATURE SENSOR INFORMATION

SOLENOID LOCATIONS AND IDENTIFICATION

INDIVIDUAL SOLENOID FUNCTION AND FAILURE RESULT

SOLENOID OPERATION

SOLENOID APPLICATION CHART

PASS-THRU CASE CONNECTORS AND WIRE HARNESS

CASE CONNECTOR TERMINAL IDENTIFICATION

CASE CONNECTOR INTERNAL COMPONENT RESISTANCE CHARTS

TCM CONNECTOR INTERNAL COMPONENT RESISTANCE CHARTS

TRANSAXLE RANGE SWITCH OPERATION AND DIAGNOSIS

STANDARD AND TIPTRONIC SHIFT QUADRANTS

TYPICAL WIRE SCHEMATIC

DIAGNOSTIC TROUBLE CODE DESCRIPTION

TORQUE CONVERTER CLUTCH OPERATION

PRESSURE TAP LOCATIONS AND IDENTIFICATION

PRESSURE SPECIFICATIONS

TRANSAXLE OIL COOLER INFORMATION

OIL PASSAGE IDENTIFICATION

CHECK FLUID LEVEL AND FLUID REQUIREMENTS

OIL PAN “STAND-PIPE” DIFFERENCES

OIL PAN AND OIL PAN GASKET DIFFERENCES

OIL FILTER DIFFERENCES

TRANSAXLE DISASSEMBLY

COMPONENT REBUILD

CONVERTER COVER ASSEMBLY

TRANSAXLE CASE ASSEMBLY

OIL PUMP ASSEMBLY

K3 CLUTCH HOUSING ASSEMBLY

K1 CLUTCH HOUSING ASSEMBLY

K2 CLUTCH HOUSING ASSEMBLY

REAR PLANETARY ASSEMBLY

FRONT PLANETARY ASSEMBLY

CENTER SUPPORT ASSEMBLY

TRANSFER DRIVEN GEAR AND FINAL DRIVE ASSEMBLY

VALVE BODY ASSEMBLY

TRANSAXLE FINAL ASSEMBLY

B2 CLUTCH CLEARANCE MEASUREMENT

F1 ROLLER CLUTCH FREEWHEEL DIRECTION

B1 CLUTCH CLEARANCE MEASUREMENT

TRANSAXLE END-PLAY MEASUREMENT

CONVERTER INSTALLED MEASUREMENT

THRUST WASHER AND BEARING IDENTIFICATION

TORQUE SPECIFICATIONS

“UPDATED” TRANSAXLE CODE INFORMATION

Language: English

Format: PDF

come back